Installation

of paving stones

Living places

The correct installation of paving stones is key to guaranteeing the durability, stability, and aesthetics of any pavement.

Phases of paving stone installation

Excavate

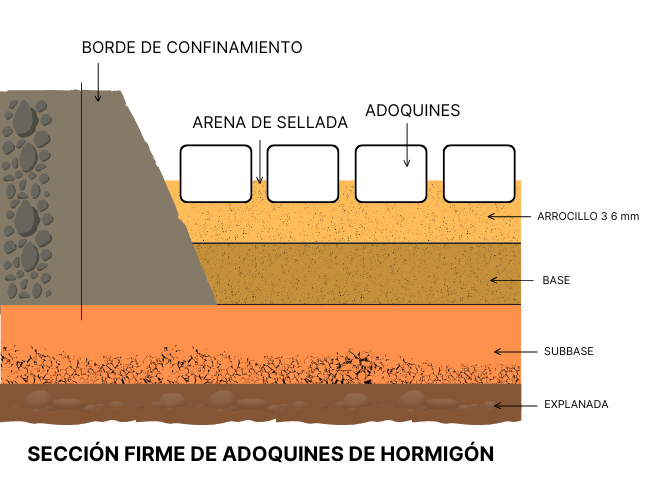

Excavate unsuitable, unstable material or unconsolidated subgrade material and compact the area that has been emptied.

Fill and level

Then fill and level with a dense aggregate suitable for subbase material (natural or artificial crushed stone), generally 15 to 20 cm of compacted subbase for pedestrian traffic and light vehicles.

The slope must be a minimum of 2%. In the case of using only crushed stone, a proctor of 99% is required.

Increase if there are other uses

If applicable, fill and level, increasing from 25 to 40 cm for heavy vehicle and industrial use, or as indicated by the engineer, architect, or landscape architect, depending on the use for which it is projected. In the case of AQUA, the thickness will be between 50 and 100 cm of 40/80 mm crushed gravel.

Build the perimeter

The entire perimeter will be constructed using rigid elements, curb or other elements in order to prevent the displacement of the paving stones. The boxing or confinement is very important.

In the case of AQUA, this layer must be completely free of fines. Correctly compacted and confined by a geotextile to prevent infiltration of unwanted materials.

Place the base

Place a base of approximately 3 or 4 centimeters with gravel (4-6 mm in diameter) leveled correctly with the help of a leveling master with longitudinal guides.

For the AQUA series, it is essential to provide a safety connection to the drainage network in the highest part of the terrain, anticipating a possible saturation of the subbase in case of extreme rainfall.

Place the pieces

The pieces are placed on the gravel layer, taking care not to step on it.

Fill the joints and compact

Once the pavement is placed, dry and fine sand will be spread over its surface, sweeping repeatedly until the joints are completely filled. In addition, it is necessary to compact them with a vibrating plate for perfect leveling.

Pavement ready

Once this process is completed, the pavement is ready for use.

Recommendations

In the installation of paving stones, the preparation of the land and the subbase is of great importance. There will be no perfect paving if there is no well-executed subbase.

Another factor to take into account in the installation is the minimum slope that must be given to the subbase, and that must be identical to that which the finished surface must ultimately have. This slope must be at least 2%.

DIMENSIONS OF SURFACES WITH PAVING STONE PAVEMENTS

The general procedure for dimensioning flexible surfaces will be followed according to the Highway Instruction. Therefore, two are the parameters that must be defined to proceed with the design of the surface: the quality of the esplanade and the level of traffic expected.

At Cleannox, we take all these aspects into account for the correct installation of paving stone pavements.

AQUA Series

This series aims to be permeable in all its layers as well as being load-bearing.